KWSP was approached by a classic car collector to re-engineer and re-manufacture a one-off gearbox cover for their 1927 Amilcar C6 Voiturette, only one of six ever imported in to the UK

The Challenge

- The only data available of the component was a grainy photograph

- The owner wanted the component to be the same concept and material as the original

The Requirements

- Adherence to the original concept and design

- In-situ testing and validation to ensure fit and functionality

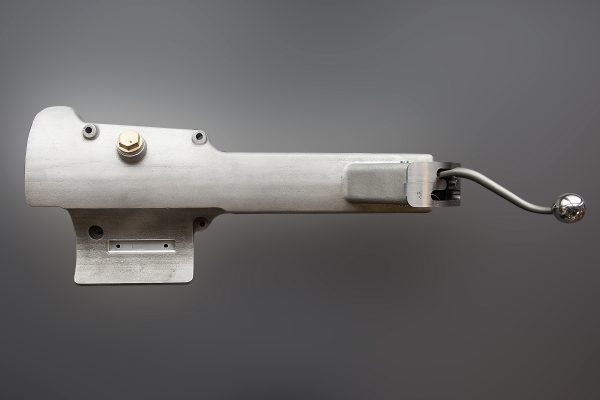

- Final component to be cast in aluminium

The Approach

- The original housing was 3D scanned and manipulated in CAD to identify mechanical interfaces and geometry

- The gearbox cover was then designed in CAD by KWSP’s engineers

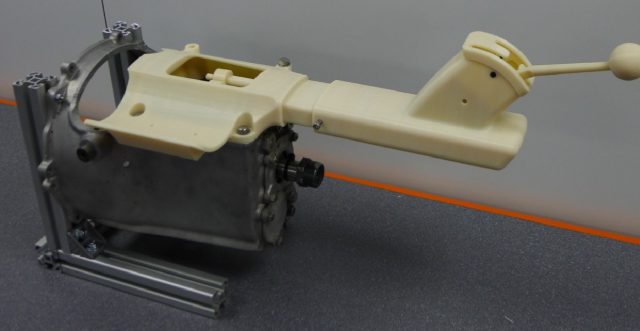

- Kinetic simulation was conducted for three linkage mechanism concepts before 3D printing the entire assembly for validation

- Casting was finally completed of the validated solution

The Results

- Confidence: Rendered 3D images of the engine cover allowed designs to be reviewed and signed off by the customer

- Speed: From creation of CAD data to functional parts manufacture took less than 24 hours

- Futureproofing: Creation and storage of a digital asset ready for future optimisation and spares

Click here for the full case study.